Acrylic Screen Printing

If you’ve tried screen printing in the past and not really enjoyed the feel of your print, you probably weren’t getting acrylic screen printing. If you had gotten acrylic water-based screen printing you’d be raving about how luxurious your print feels because you’d be feeling the fabric more than the ink! That’s because acrylic water-based screen printing uses specially formulated water based inks that allow you to get ultra-soft hand to your prints without compromising color quality at all. AMBRO Manufacturing offers custom screen printing using water-based acrylic inks.

Acrylic Screen Printing

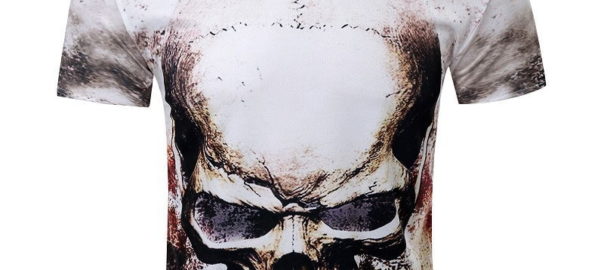

Most typical screen printing is done with plastisol inks, which are fine for plenty of uses, however they aren’t ideal for certain lightweight fabrics, fashion prints, and all over coverage designs. The problem is that they lack a solvent and are comprised of micro-plastic solids which means when you send them through a heater to cure the print feels tougher and a bit heavier than when wet. Acrylic inks are created differently so they won’t leave behind a rough hand while still giving you solid color and great coverage. In fact, acrylic water-based screen printing is really the only way to do all over prints since you’ll be covering most of the garment with ink and you don’t want it to feel like a leaded apron! Unless you are planning to go to the dentists for some x-rays, you won’t want your t-shirt feeling like a lead blanket.

The primary difference between using water-based screen printing inks and plastisol inks can be noticed in the final feel of the print. Typically, plastisol inks feel heavy and like a plastic or rubber, where water-based inks have a very light feeling and are hardly noticeable to the touch. Where consumers would commonly see water-based screen printed tees would be at a concert. Most multi-color concert tees are printed using this ink set.

The strategy behind choosing a water-based ink comes down to the number of colors used in the design. Since each color requires more ink on the fabric, the heavier the fabric will become. If you are developing a project that requires one color of print, while you could use water-based inks, it’s not necessary. However, if that project was 9-10 colors, water-based inks would be recommended.

So if you are interested in doing custom acrylic water-based screen printing you only need to reach out to one of our representatives and we’ll be happy to get you set up from there. Don’t worry if you don’t have your art finalized, we can walk you through the entire process and you can work closely with our art staff to get your order done.

We always keep open lines of communication so that you can ask questions and receive assistance whenever necessary, so you’re never alone because there is someone here to help you. If you want to place an order with us for custom acrylic water-based screen printing, or if you would like to learn more about our company and all of the customization services we have to offer, you can contact us by email or by giving us a call at (908) 806-8337.