Simulated Process Screen Printing

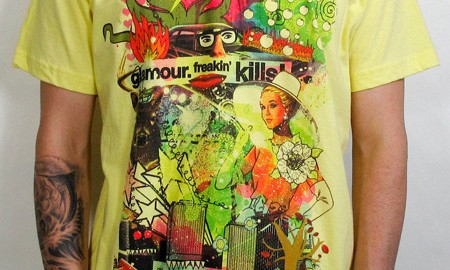

Simulated Process Screen Printing is a special screen printing method that allows screen printers to print in full color, high resolution quality and reproduce photo realistic results on dark garments.

Traditional 4 color process printing, not simulated, is used when printing on white garments, but when switching to dark garments, Simulated Process Screen Printing is required.

Where as a traditional 4 color process printing job is truly 4 colors, a simulated process screen printing job is typically 4 to 6 colors and depending on the design may be up to 10 colors.

Simulated Process Screen Printing

The process of Simulated Process Screen Printing relies on specialized custom inks that are opaque (can be seen through) and a software process of separating the colors of the original artwork into the 4 distinct colors required to produce the desired outcome.

As you are aware, your television can produce realistic images using only Red Green and Blue, in a similar technique, Simulated Process Screen Printing uses 4 colors and a white underbase to create the desired photo realistic effect for your garment.

AMBRO Manufacturing is a professional cut and sew, garment, fabric and textile decorating company based in New Jersey. Our specialties include : Jumbo Screen Printing, Over Sized Screen Printing, Sublimation Printing, Embroidery, Cut and Sew and Simulated Process Screen Printing as well as 4 color process printing.

Our expert team of garment engineers will help you walk through the process of developing the perfect Simulated Process Screen Printing garment. Speaking with us in advance of your project will ensure a great outcome.

We often find that our customers ask us for a specific item using a specific process, when there may be a better process that will yield better results. It is for this reason that we approach each project as a consultative approach to ensure your satisfaction and a high quality product.

If you are interested in Simulated Process Screen Printing, please consider giving us a call (908) 806-8337 or email us.